How it works

Pavestech's Tracblast system is a retexturing process designed to Renew, Restore or Improve the original design properties of the road surface with regard to texture and skid resistance.

Pavestech's Tracblast system uses the latest technology computer controlled High Velocity Impact Method (HVIM) of Retexturing Asphalt and Concrete road surfaces.

The mechanical process removes surface contaminants, surface imperfections and coatings, is fully controlled, safe and environmentally sound. It uses no water, no chemicals or solvents, emits no pollutants or dust to the atmosphere and the removed material can be fully recycled.

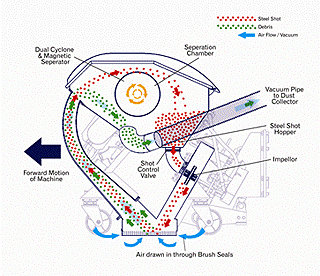

The steel shot impacts the surface and bounces off, as it does so material from the surface whether this is contaminants, coatings or the surface material itself is abraded and loose material together with the shot is drawn up into the machine by the airflow created by the vacuum unit.

Brush seals enclose the blast head to the surface and air is drawn in through and under the brushes from the surface to ensure no shot or material from the blast head escapes to atmosphere.

The debris and shot is drawn up into the separation chamber and by a dual cyclone and magnetic separation process the debris is drawn off to the dust collector and the shot is recycled back to the blast head.

The strength or degree of blasting required is infinitely variable and will depend on what the surface requires.