Our Equipment

Truckblaster

Pavestech's Trackblast Unit is a completely self contained highway retexturing system. It operates like a modern factory process with everything carefully monitored and controlled via sensors and cameras which feed in to the on board computer where the operator can make adjustments and control speed and texture levels via the touch screen.

Total dust extraction and shot separation is achieved via the vacuum system with 24 specialist filter cartridges and a large magnetic drum. All shot is recycled immediately and dust stored for recycling into new asphalt production later.

Powered by a 6 cyl 10.8 litre diesel truck unit when in work mode it changes to hydrostatic drive giving accurate speed control for precise retexturing levels. Moving along at a walking pace it can fully retexture up to 3000m2 per hour.

The blast head can side shift fully left to fully right allowing full carriageway width to be achieved while the truck is still in the centre of the lane. Safety features include the latest technology dead man switches located inside the cabin as well as 2 inside the truck body. In front of the truck there's a double flashing light bar for traffic approaching in opposite direction. Latest technology of flash lights, located on the rear of the truck body with different patterns for optimum safety during day and night for personnel as well for traffic approaching from behind.

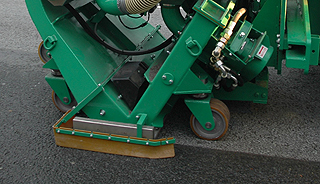

Ride On Unit

Pavestech's Smaller Ride On Unit is a self contained retexturing blaster for the smaller jobs where the large truck unit is not practical. Often used in support of the truck to do the awkward areas in central crossovers or roundabouts.

The operator has excellent visual view of the blasting and very easy instant control. Dust extraction and shot separation is achieved via the vacuum system with specialist filter cartridges. All shot is recycled immediately and dust stored for recycling into new asphalt production later.

Powered by a modern diesel engine with hydrostatic drive giving accurate speed control for precise retexturing levels. Moving along at a walking pace it can fully retexture up to 350m2 per hour.

Hand Operated Unit

This unit is electrically powered from the generator in the support truck and a dust collector is connected via a vacuum hose. The twin blast wheels give a very high performance blasting with results equal to the large truck unit. The unit is highly manouverable and is very suitable for jobs which require a high quality finish or are difficult to access. The 500mm wide blast head can achieve work rates of up to 400m2/hr.

Dust Collector

The dust collector unit is connected via a vacuum hose and can be up to 20m from the blast head it is only used in conjunction with the hand operated machine. The high quality filtration ensures no dust is emitted to the atmosphere.

Magnetic Sweepers

Magnetic sweepers are used to sweep the surface after retexturing to collect any steel shot which may be left behind, the collected shot is then recycled by the retexturing unit.

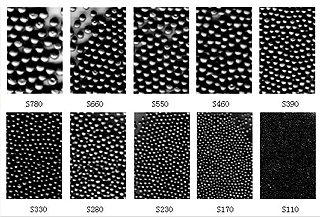

Blast Media

The Pavestech retexturing process uses a round steel shot to impact and abrade the surface. The high quality shot is an aspherical product made of hypereutectoid steel that has been heat treated to a tempered martensite structure providing maximum breakdown resilience and long working life. The size of shot used ranges from S930 (2.3mm) to S330 (0.70mm) depending on the surface material to be retextured and the finish required.

Griptester

The equipment we use to carry out skid resistance surveys is a Griptester Skid Resistance (Surface Friction) Tester Mark 2 "D" axle. The Griptester is a braked wheel, fixed slip device. It is operated in accordance with the British Standard BS7941: Part 2: 2000.

The towing vehicle is fitted with a water tank, pump, pipework and automatic control system for self-watering in front of the measuring wheel. The effect of depositing water in front of the measuring wheel is to provide a water film between the measuring tyre and the road surface being tested, simulating wet road conditions.

The Griptester has excellent correlation with other long established friction testers including SCRIM and pendulum. The TRL have confirmed a strong linear relationship between measurements of skid resistance made by SCRIM and by Griptester at 50km/hr.

The information stored for each survey run includes: site name,, direction, wheel track, distance, speed, GPS location, water flow and grip number.

Pendulum Skid Friction Tester

We also use the pendulum tester for spot checks during retexturing works.

The Pendulum Portable Skid Tester was first developed at the UK Transport Research Laboratory in 1960 to test road surfaces. It is recognised globally as a useful means of checking the skid resistance of many surfaces including floors.

The apparatus measures the frictional resistance between a rubber slider (mounted on the end of a pendulum arm) and the test surface. It is also used in the laboratory for measuring the PSV of aggregates, while it has been largely superceded by continuous friction measuring equipment (CFME) devices, it still has a useful roll on site for spot checks during retexturing works.

EN 13036-4, Road and airfield surface characteristics - Test methods - Part 4: Method for measurement of slip/skid resistance of a surface - The pendulum test.

Sand Patch Test

The so-called "sand-patch method" has been used worldwide for many years to measure the road surface texture.

It relies on a given volume of sand which is spread out on a road surface. The sand is distributed to form a circular patch, the diameter of which is measured. By dividing the volume of sand with the area covered, a value is obtained which represents the average depth of the sand layer, i. e. an average "texture depth".

EN 13036-1, Road and airfield surface characteristics - Test methods - Part 1: Measurement of pavement surface macrotexture depth using a volumetric patch technique.

We sometimes use this test, but much prefer to use the outflow meter as it provides much more meaningful information.

Surface Hydroconductivity Testing

Accurately measures the road surface’s ability to dispel water from under the tyre.

Quick, Easy to use and consistently accurate the meter provides a more meaningful measure of the potential for wet skidding or aquaplaning than texture depth measurement does.

The device is a self contained outflow meter.

It is a hands-off operation with consistently accurate results regardless of the operator as long as the tests are performed in accordance with instructions.

The base sealing ring simulates a tyre footprint.

A measured volume of water is released in the centre of the sealing ring while an electronic timer indicates how long it takes the water to pass through the surface texture.

The test also provides a graphic visual display of escaping water.

E 2380 - 05 Standard Test Method for Measuring Pavement Texture Drainage Using an Outflow Meter.